About Primus

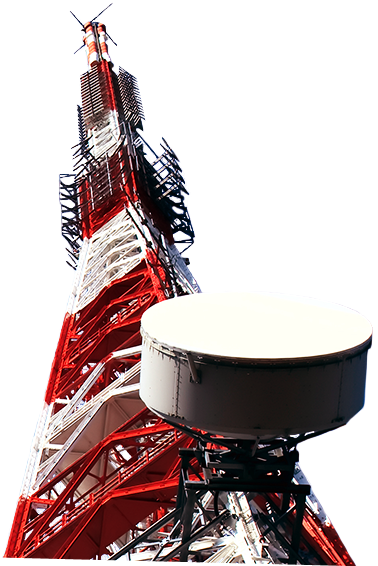

Across the country and across generations, Primus delivers solutions that power businesses, government, education, and research, connecting individuals and entire communities. Primus will help you in the planning, design, and construction of high-performing, cost-efficient communications solutions.

Quality Offerings

Primus offers complete supply chain solutions for the most reliable, innovative configurations

featured products

Watch our Services Video

Primus will help you in the planning, design, and construction of high-performing, cost-efficient communication solutions.

Give us a ring, we are ready to help

Our knowledgeable team is always ready to assist your requests with live immediate support. We have live technical support for you!